Cold and deep-freeze rooms

for trade and industry

KRAMER cold rooms meet the highest requirements in terms of energy efficiency and food safety. Our refrigeration and deep-freeze solutions are designed to ensure the perfect fit and facilitate optimal processes.

Keeps values

fresh

Maximum energy efficiency

Europe-wide refrigeration solutions and service

More than 95 years of experience

Cold rooms for trade and industry

Precise cold rooms

with maximum energy efficiency

Food legislation authorities rightfully place stringent demands on cold rooms. When planning our services, we prioritise both exceptional energy efficiency and seamless integration within the operational framework. This is how we actively contribute to environmental preservation, guarantee ideal processes and effectively reduce operating expenses.

Conventional wall structure

or with panels

A conventional wall structure for cold rooms features tiled surfaces that include a vapour barrier, insulation and a fabric filler applied beneath the tiles on the masonry.

To achieve a surface that is totally food-safe, smooth and easy to clean, we recommend the utilisation of insulation panels. The surface is crafted using galvanised steel or, in cases of increased demands, stainless steel.

For reasons of hygiene, ceilings are always installed as industrial panels.

Conventional floor structure

or with FastIn® system flooring

In traditional cold room construction and warehouse technology, the conventional approach involves utilising EPS floor insulation and concrete screed.

Our FastIn® system flooring is used in small-scale cold room construction as well as for refrigeration cells in the catering sector. Even when renovating and converting existing buildings, the FastIn® system flooring can be employed to create cold rooms with minimum floor construction work.

The surface finish options include tiles, stainless steel as well as UCRETE or epoxy resin coatings.

Cold room doors and entrances

Depending on your specific operational requirements, the entrances to your cold room can be custom designed:

- Cold room doors are available as hinged doors, sliding doors, swing doors or walk-in sliding doors

- Fire doors/gates

- Strip curtains, inspection hatches and glazed removal windows

- Locks and equipment: Press lever latches with profile cylinder lock, magnetic lock, inspection window, pipe passage, overhead door closer and magnetic door contact switch

To guarantee optimal hygiene, we use steel sheet or stainless steel for the door surfaces.

Cold room equipment

for optimal safety and efficient processes

Shelves

Upon request, we can equip your cold room with free-standing shelves manufactured from either aluminium or stainless steel. Shelving made of aluminium, plastic or stainless steel is also available.

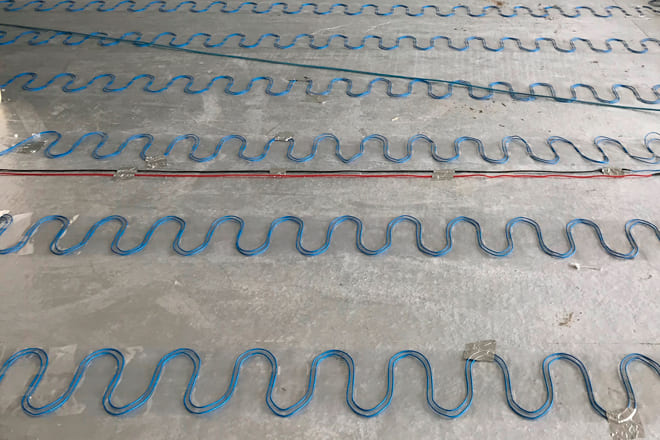

Traffic route heating system

Icing can occur on the flooring at the entrance to deep-freeze rooms. We avoid this problem and ensure seamless operation by employing a traffic route heating system.

Frost protection heating

To prevent frost damage caused by frozen moisture beneath the cold room, frost protection heating is used.

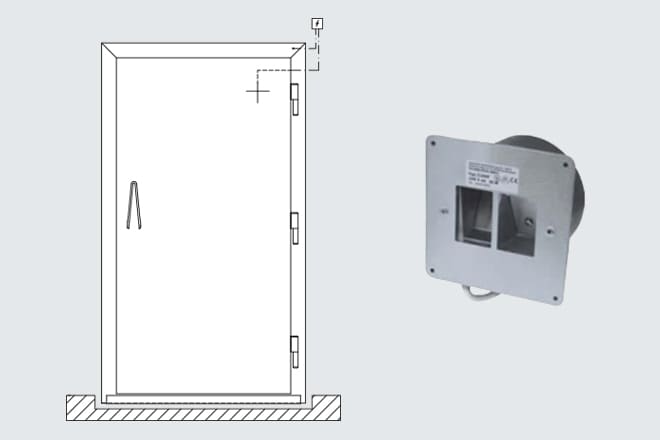

Pressure equalisation valve

We utilise a pressure equalisation valve to effectively manage pressure fluctuations that arise during processes like defrosting air coolers. Pressure equalisation valves can often be integrated into the door.

Fire protection switch

Depending on the specific purpose of the room, the installation of a fire protection switch is required by law. For reasons of safety, we always install one.

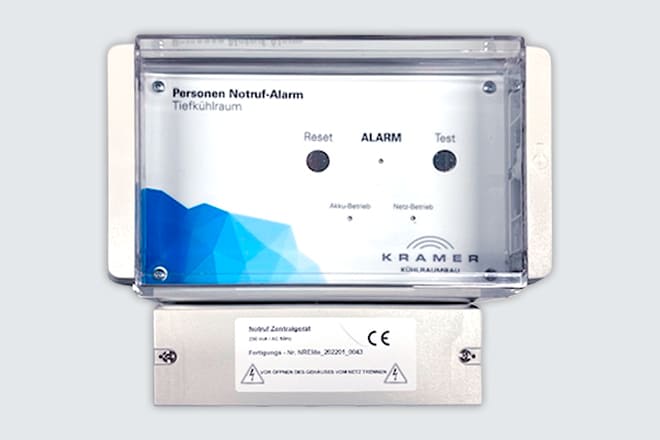

Emergency alarm systems

The emergency alarm system was specifically designed to enhance the safety of employees working in cold and deep-freeze rooms, ensuring swift assistance is summoned in case of any emergency.

Flat light LED®

Our elegant, ultra-flat LED panels, boasting exceptional luminance, deliver uniform illumination throughout the cold room. The flat design effectively eliminates uncontrolled air turbulence caused by the refrigeration unit.

Ceiling hatch

Ceiling hatches can be integrated into cold rooms to enhance ventilation. To ensure proper functioning in deep-freeze rooms, a heated frame can be employed.

Glazing and anti-ram barriers

Anti-ram barriers and posts enhance the safety and security of cold rooms. Glazing helps to keep the contents and processes inside the cold room visible.

Do you have specific requirements? We are happy to advise you.

Simply write to us or give us a call. Together we will find the solutions to your individual challenge.

+49 7665 9359-0

info@kramer-gmbh.com

Reference projects of our industrial customers

Leading companies place their trust in

KRAMER refrigeration solutions.

Which project can we implement for you?

Your message to us.

YOUR CONTACT

for cold room construction

Alexander Butsch and his team are experts in the design and execution of cold room solutions.